SAVINGS DURING MACHINING - Exceptional savings potential

Solutions for swarf processing provide an exceptional potential for savings due to reduced labour costs, the re-use of valuable coolants and oils and the sales of swarf.

Swarf crushers are often the first step in swarf processing plants to ensure smooth transport. The size of the swarf is reduced and transport is thus facilitated, especially for above-ground systems.

Swarf crushers are also ideal as a standalone solution for reducing mass and the resulting transportation costs.

Reasons for Swarf crushing

- Reduced transport volume, thereby lower transport costs (up to 15% of the original volume possible)

- Preparation for use in swarf drying centrifuges for the recovery of cooling lubricants from the swarf

- Preparation for use in aboveground return pumping systems for conveying swarf and cooling lubricant

- Preparation for supplying swarf in briquetting presses

- Automated removal of blockages and coarse parts

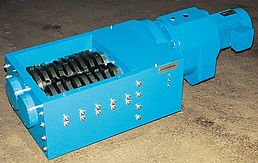

TA CRUSHER

TA (Twin Shaft) shredder for greater throughput in a compact package

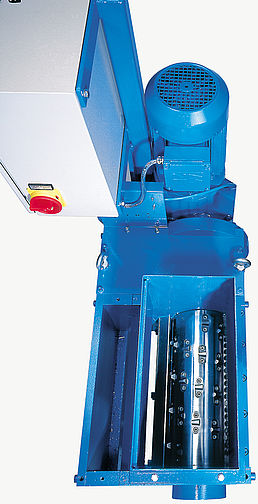

MA CRUSHER

The patented one shaft crusher with automatic ejector of large parts.

MSA CRUSHER

2-shaft crusher for hard and brittle material

VC CRUSHER

Vertical crusher for for surge load of the swarf