Our Products

Mayfran International is a manufacturer of hinged belt conveyors for chip and coolant removal from machine tools along with paper belt filters, and systems for processing chips and cutting lubricants in the metalworking industry. As an original equipment manufacturer for machine tool manufacturers, the company is present worldwide at locations in the United States, Europe, Japan, Korea, India and China.

Mayfran International designs, manufactures, installs and services chip and coolant systems for all types of metalworking machinery, including stand alone and central filtration systems. Transportation plants for automotive press stamping scrap, waste and recycling systems above-ground chip and coolant return pump systems, chip centrifuges, shredders, individual pumping stations and centralized vacuum systems for metal and non-metal composites.

MACHINE TOOL PRODUCTS

Swarf conveyor

For more than 50 years Mayfran has been producing swarf conveyors for the machine tool industry. The first patent for a hinged belt conveyor dates back to 1952. In North America the Mayfran product name “Chiptote“ has become synonymous with chip conveyor. We produce steel hinged belts, scraper conveyors and screw conveyors. These conveyors can be provided with the following optional add-ons: Machine pumps, oil-skimmers or additional coolant containers.

HINGE STEEL BELT CONVEYOR

HINGE STEEL BELT MT 10

Compact designed conveyor for small machine tools

HINGE STEEL BELT CT 20

Widest range of operations for medium sized machine tools

HINGE STEEL BELT CT 2

Solid conveyor for lathes and big machine tools

HINGE STEEL BELT CLEANSWEEP G2

Reduced maintenance with exchangeable screenbox and integrated screwconveyor

4 inch conveyor

Hinge belt conveyor for swarf and scrap (up to 70 mtr.)

6 inch conveyor

Hinge steel belt used as transport system for swarf and press scrap transport

Consep System

Conveyor with integrated coolant cleaning

DRAG LINK CONVEYOR

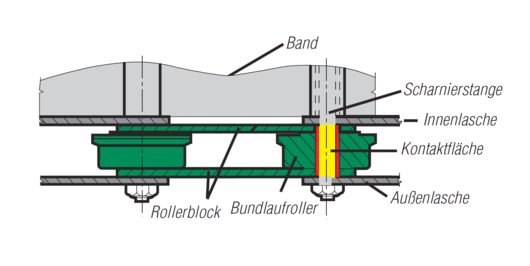

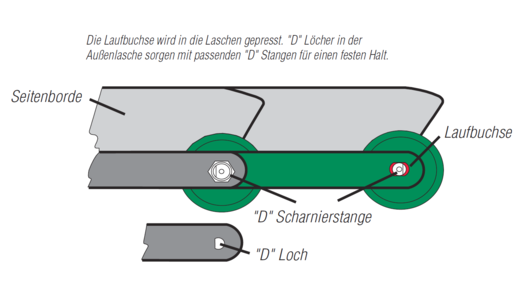

Belt technology

Our steelbelt conveyors incorporate years of experience into the design ensuring a long and reliable life.

The hinged steelbelt is available in various designs, depending on the application.

Special features for severe applications are available.

Belt plates with perforated or dimpled surfaces, welded loops, reinforced belt plates and reinforced cleats can be supplied for special applications.

Chain design

The belt pull is borne solely by the chains, thus reducing the tension on the belt plates. Standard belt widths are available from 305 mm to 2134 mm in 6˝ steps depending on the type of belt.

For more information, see following film

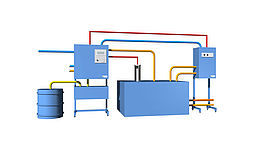

INDIVIDUAL FILTRATION SYSTEMS

The filter systems of the Mayfran Modular Filter System, MMF for short, offer a suitable solution for every machining process. Due to the modular design, the filter system is optimally adapted to the respective requirements. An MMF filter system essentially consists of containers, filters, pumps and other options. The advantages of cooling lubricant treatment are numerous, ranging from an increase in coolant service-life, through to smaller quantities of waste and wastewater, right up to an improvement in surface quality with less tool wear.

MMF Mayfran Modular Filter System

Conveyor-filter combination

consep system

Conveyor with integrated coolant cleaning

Mayfran Accessories - Add value to your business !

Mayfran accessories are created as your machine or system is developed and are therefore tailored to each individual application. Alongside this Mayfran accessories always embrace the latest technology ensuring the end result is always state-of the-art. Our accessories program is tailored to your needs based on decades of experience in many industries, such as the machine tool, aerospace and automotive. Existing technology can be upgraded for your individual needs and with optimal solutions. We would be pleased to support you throughout the entire life cycle of your machine or plant!

AT-Cleaner

Additional by pass coolant cleaning

HIGH PRESSURE SYSTEMS

High pressure units for cooling directly through the spindle

refillmatic

Automatic control of volume and conditions of cooling lubricants

Tube skimmer W40

removes floating oil from other liquid media

COOLANT FILTRATION / SWARF PROCESSING

Conveying Systems

4 inch conveyor

Hinge belt conveyor for swarf and scrap (up to 70 mtr.)

6 inch conveyor

Hinge steel belt used as transport system for swarf and press scrap transport

viavent

Closed over the floor pumpback ystem for coolant and swarf

shuffle conveyor

Shuffle conveyor for parts and swarf

powertrof pushbar conveyor

Under the floor conveyor for bushy sward and long distances

swarf vacuum systems

Swarf Blowing or Suction Systems directly at the machine Tool

scrap or swarf loading systems

Automatic Removal Systems for swarf or other metal scrap

Coolant Filtration Systems

MCF precoat filter

Compact precoat Filter system for highest coolant filtration quality.

pressure belt filter

Filter for turnings and grinding applications

mvf vacuum belt filter

Coolant filter used for central coolant cleaning for several machine tools.

Vertidrum

Drum belt filter for a large amount of coolant

Swarf processing systems

Mayfran offers turnkey, compact systems for chip processing, including shredding & drying of chips and the economic recovery of cooling lubricant. Environmentally it is becoming increasingly important to process chips to ensure safe transportation. Processing also recovers cooling lubricants and provides higher value dry chips.

Significant cost savings are achievable through coolant reclamation, higher scrap values & reduced transport costs due to volumetric reduction.

Chip processing is both environmentally and financially sound, as the following example shows.

Say a machine shop produces 500kg of steel chips per hour in a three-shift 24 hour operation(12000kgs/day) working 5 days a week. Their residual moisture content is around seven percent by weight of emulsion. Deducting the residual emulsion after centrifuging results in about 50 g of emulsion per kilogram of chips. In this specific case, that is around 600 kg of recovered oil per day or almost 140,000 litres per year. With a price per litre of around three euros, the corresponding investment will be quickly paid off.

The 5 major advantages at a glance

- Mayfran offers complete solutions for environmentally conscious chip disposal

- Thanks to the modular design of Mayfran components, swarf processing systems can be configured to suit the customer's specific requirements in terms of size, type and available space

- Cost savings due to high recyclability of metal chips, cooling lubricants along with reduced transport.

- Rapid amortisation due to maximum economic efficiency

- Consistent project management

VBU centrifuges

continuous swarf feeding centrifuge

LBC centrifuges

Lift bottom centrifuge for batch load

TA Crusher

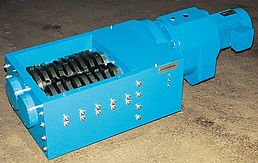

TA (Twin Shaft) shredder for greater throughput in a compact package

MA Crusher

The patented one shaft crusher with automatic ejector of large parts.

MSA Crusher

2-shaft crusher for hard and brittle material

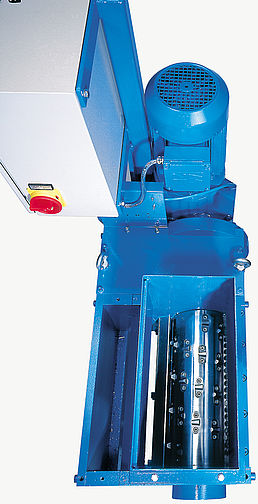

VC Crusher

Vertical crusher for for surge load of the swarf

Mayfran Accessories - Add value to your business!

Mayfran accessories are created as your machine or system is developed and are therefore tailored to each individual application. Alongside this Mayfran accessories always embrace the latest technology ensuring the end result is always state-of the-art.

Our accessories program is tailored to your needs based on decades of experience in many industries, such as the machine tool, aerospace and automotive. Existing technology can be upgraded for your individual needs and with optimal solutions. We would be pleased to support you throughout the entire life cycle of your machine or plant!

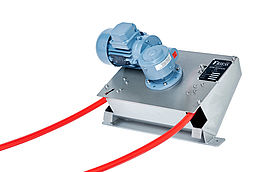

Pumpstations

Machine pump back systems can be retrofitted to any machine tool.

Refillmatic

Automatic control of volume and conditions of cooling lubricants

SCRAPTRANSPORT / RECYCLING

MORE INFORMATION

Ash Conveyors and Steel belts for Ash Handling

With over 30 years of experience in providing solutions for handing scrap from shears to hundreds of scrapyards around the world, Mayfran is a proven leader in high reliability systems.

More information in our brochures

Ash conveyors for Incineration plants

Conveyor for municipal solid waste / biomass waste / hazardous waste incineration