RECYCLING-INDUSTRY

Mayfran produces innovative and efficient material handling equipment for the recycling industry.

Our steel plate belt conveyors are used in the following industries:

- steel and metal recycling

- scrap processing

- press shops

- punching shops

- waste processing

- waste incineration plants

- ashes disposal

- recycling plants

- foundries

- waste wood recycling

With our conveyor technology we transport

- cast iron and steel chips

- press and punching scrap

- chip briquettes

- scrap metal packages

- electronic scrap

- cast and forged parts

- wood waste such as wood chips

- waste and recycling materials

Our solutions are characterized by exceptional conveying capacities, wear resistance and robustness as well as availability requirements and are designed for various applications.

For more complex requirements, we develop complete conveyor systems, such as sheet metal scrap disposal systems, which are used to dispose of entire production plants by means of container changing systems by combining various individual conveyors and movable chutes.

With decades of experience, Mayfran designs systems to meet solution-oriented and industry-specific requirements.

scrap / solid waste

MORE INFORMATION

ash conveyors

Ash Conveyors and Steel belts for Ash Handling

With over 30 years of experience in providing solutions for handing scrap from shears to hundreds of scrapyards around the world, Mayfran is a proven leader in high reliability systems.

More information in our brochures

Ash conveyors for Incineration plants

Conveyor for municipal solid waste / biomass waste / hazardous waste incineration

belt technology

Belt technology

Our steelbelt conveyors incorporate years of experience into the design ensuring a long and reliable life.

The hinged steelbelt is available in various designs, depending on the application.

Special features for severe applications are available.

Belt plates with perforated or dimpled surfaces, welded loops, reinforced belt plates and reinforced cleats can be supplied for special applications.

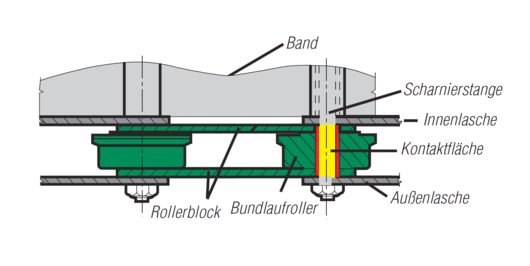

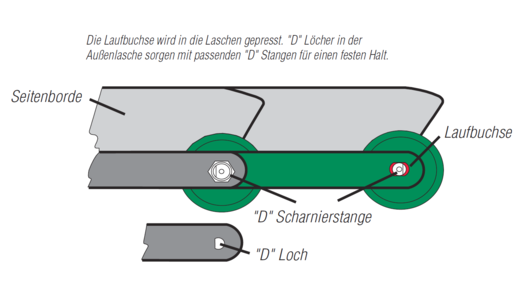

Chain design

The belt pull is borne solely by the chains, thus reducing the tension on the belt plates. Standard belt widths are available from 305 mm to 2134 mm in 6˝ steps depending on the type of belt.