Solutions and products for machine tools

Mayfran International has continuously adapted the technique for swarf conveying and coolant cleaning to the progressive development of machine tools. New processing technologies like for example lathes and milling machines are in need of new concepts for swarf disposal.

MORE INFORMATION

swarf conveyor

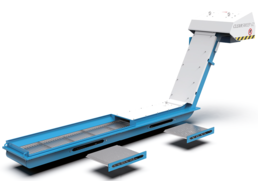

Swarf conveyor

For more than 50 years Mayfran has been producing swarf conveyors for the machine tool industry. The first patent for a hinged belt conveyor dates back to 1952. In North America the Mayfran product name “Chiptote“ has become synonymous with chip conveyor. We produce steel hinged belts, scraper conveyors and screw conveyors. These conveyors can be provided with the following optional add-ons: Machine pumps, oil-skimmers or additional coolant containers.

HINGE STEEL BELT CONVEYOR

HINGE STEEL BELT MT 10

Compact designed conveyor for small machine tools

HINGE STEEL BELT CT 20

Widest range of operations for medium sized machine tools

HINGE STEEL BELT CT 2

Solid conveyor for lathes and big machine tools

HINGE STEEL BELT CLEANSWEEP G2

Reduced maintenance with exchangeable screenbox and integrated screwconveyor

4 inch conveyor

Hinge belt conveyor for swarf and scrap (up to 70 mtr.)

6 inch conveyor

Hinge steel belt used as transport system for swarf and press scrap transport

Consep System

Conveyor with integrated coolant cleaning

DRAG LINK CONVEYOR

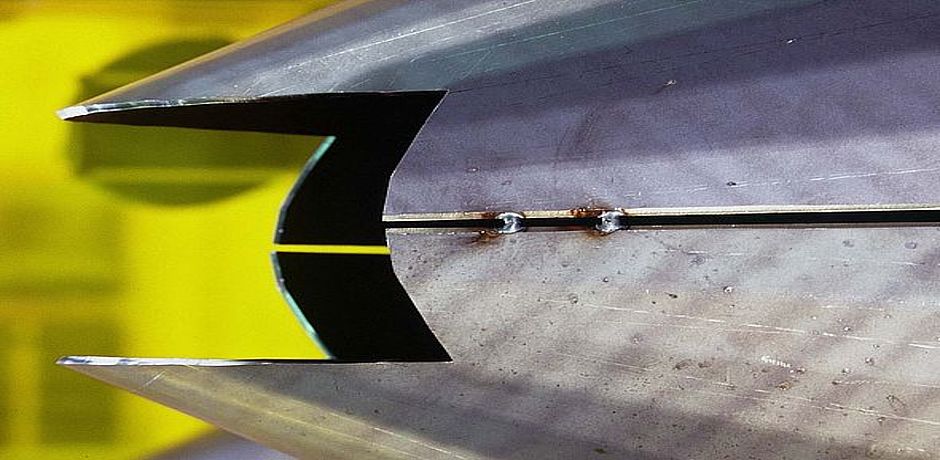

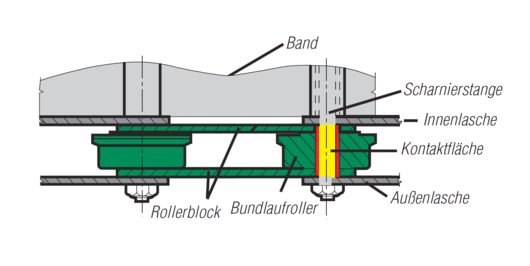

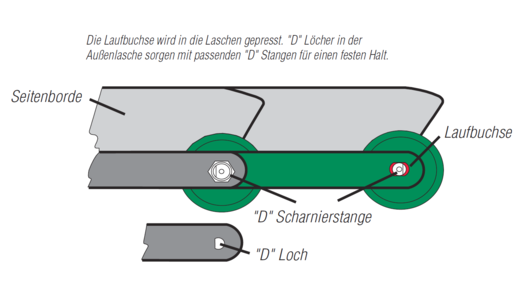

belt technology

Belt technology

Our steelbelt conveyors incorporate years of experience into the design ensuring a long and reliable life.

The hinged steelbelt is available in various designs, depending on the application.

Special features for severe applications are available.

Belt plates with perforated or dimpled surfaces, welded loops, reinforced belt plates and reinforced cleats can be supplied for special applications.

Chain design

The belt pull is borne solely by the chains, thus reducing the tension on the belt plates. Standard belt widths are available from 305 mm to 2134 mm in 6˝ steps depending on the type of belt.

For more information, see following film

single filter

INDIVIDUAL FILTRATION SYSTEMS

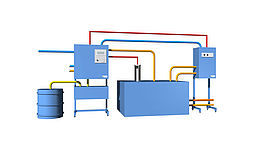

The filter systems of the Mayfran Modular Filter System, MMF for short, offer a suitable solution for every machining process. Due to the modular design, the filter system is optimally adapted to the respective requirements. An MMF filter system essentially consists of containers, filters, pumps and other options. The advantages of cooling lubricant treatment are numerous, ranging from an increase in coolant service-life, through to smaller quantities of waste and wastewater, right up to an improvement in surface quality with less tool wear.

MMF Mayfran Modular Filter System

Conveyor-filter combination

consep system

Conveyor with integrated coolant cleaning

fittings

Mayfran Accessories - Add value to your business !

Mayfran accessories are created as your machine or system is developed and are therefore tailored to each individual application. Alongside this Mayfran accessories always embrace the latest technology ensuring the end result is always state-of the-art. Our accessories program is tailored to your needs based on decades of experience in many industries, such as the machine tool, aerospace and automotive. Existing technology can be upgraded for your individual needs and with optimal solutions. We would be pleased to support you throughout the entire life cycle of your machine or plant!

AT-Cleaner

Additional by pass coolant cleaning

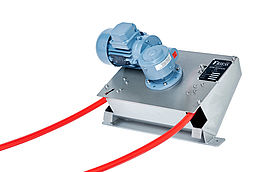

HIGH PRESSURE SYSTEMS

High pressure units for cooling directly through the spindle

refillmatic

Automatic control of volume and conditions of cooling lubricants

Tube skimmer W40

removes floating oil from other liquid media