Swarf processing systems

Mayfran offers turnkey, compact systems for chip processing, including shredding & drying of chips and the economic recovery of cooling lubricant. Environmentally it is becoming increasingly important to process chips to ensure safe transportation. Processing also recovers cooling lubricants and provides higher value dry chips.

Significant cost savings are achievable through coolant reclamation, higher scrap values & reduced transport costs due to volumetric reduction.

Chip processing is both environmentally and financially sound, as the following example shows.

Say a machine shop produces 500kg of steel chips per hour in a three-shift 24 hour operation(12000kgs/day) working 5 days a week. Their residual moisture content is around seven percent by weight of emulsion. Deducting the residual emulsion after centrifuging results in about 50 g of emulsion per kilogram of chips. In this specific case, that is around 600 kg of recovered oil per day or almost 140,000 litres per year. With a price per litre of around three euros, the corresponding investment will be quickly paid off.

The 5 major advantages at a glance

- Mayfran offers complete solutions for environmentally conscious chip disposal

- Thanks to the modular design of Mayfran components, swarf processing systems can be configured to suit the customer's specific requirements in terms of size, type and available space

- Cost savings due to high recyclability of metal chips, cooling lubricants along with reduced transport.

- Rapid amortisation due to maximum economic efficiency

- Consistent project management

VBU centrifuges

continuous swarf feeding centrifuge

LBC centrifuges

Lift bottom centrifuge for batch load

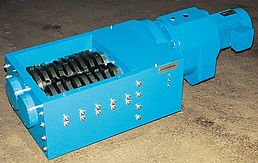

TA Crusher

TA (Twin Shaft) shredder for greater throughput in a compact package

MA Crusher

The patented one shaft crusher with automatic ejector of large parts.

MSA Crusher

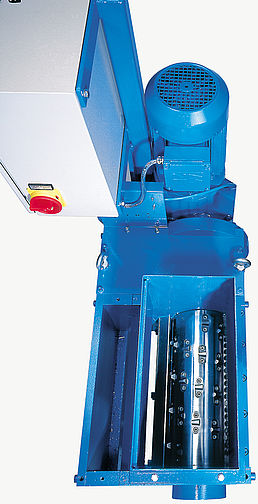

2-shaft crusher for hard and brittle material

VC Crusher

Vertical crusher for for surge load of the swarf