Stamping and press-industry

Mayfran produces innovative and efficient material handling equipment for the stamping and press-industry.

Our solutions are characterized by exceptional conveying capacities, wear resistance and robustness as well as availability requirements and are designed for various applications.

For more complex requirements, we develop complete conveyor systems, such as sheet metal scrap disposal systems, which are used to dispose of entire production plants by means of container changing systems by combining various individual conveyors and movable chutes.

With decades of experience, Mayfran designs systems to meet solution-oriented and industry-specific requirements.

hinge belt conveyor

CONVEYOR FOR PARTS AND PRESS SCRAP

Mayfran has years of experience providing solutions for managing metalforming scrap. Hundreds of major stamping facilities around the world utilize Mayfran equipment for its outstanding reliability and long life.

4 Inch hinge belt conveyor

Hinge belt conveyor for transport of chips and scrap parts over long distances of up to 70 m.

6 inch hinge belt conveyor

Hinge belt conveyor for transport of chips and scrap parts over long distances of up to 100 m.

Shuffle Conveyor

Shuffle Drive Conveyor

Mayfran’s Shuffle Drive Conveyor will significantly increase uptime, reduce setup time, eliminate draw on shop air and run reliably shift after shift after shift. The return on investment through increased machine utilization is astounding. That’s why most of our customers have already installed multiple Shuffle Drive Conveyor systems, and are planning to install more.

Each element is designed to provide quiet, reliable service for years of operation. The Shuffle Drive Conveyor will probably outlast the systems it supports, whether implemented at the press or as part of a centralized scrap collection system.

More Information

shuffle conveyor

Shuffle conveyor for parts and swarf

press-mounted shuffle conveyor

Press-mounted shuffle drive solution for efficient transport of punching and press scrap

belt technology

Belt technology

Our steelbelt conveyors incorporate years of experience into the design ensuring a long and reliable life.

The hinged steelbelt is available in various designs, depending on the application.

Special features for severe applications are available.

Belt plates with perforated or dimpled surfaces, welded loops, reinforced belt plates and reinforced cleats can be supplied for special applications.

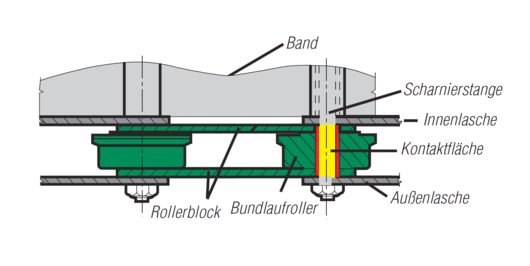

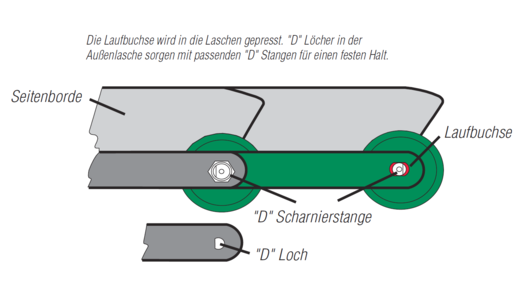

Chain design

The belt pull is borne solely by the chains, thus reducing the tension on the belt plates. Standard belt widths are available from 305 mm to 2134 mm in 6˝ steps depending on the type of belt.